CFD simulations involving 3D complex geometry have become the norm, however, this hasn’t lessened the…

Meshing Santa’s Hat

In this month’s blog, we are ending 2020 on a festive note, by using Pointwise to mesh Santa’s hat with Pointwise’s new Automatic Surface meshing. Automatic Surface meshing is now available in Pointwise v18.4R2.

Import CAD

We begin meshing Santa’s hat by importing the Solidworks CAD file, and this resulted in the database shown in Figure 1.

Cleaning CAD

The CAD cleanup is made easier by placing different parts of the database into layers, including the “Merry Christmas” letters. CAD cleanup consisted of merging some quilts and “Trim by Surface” to intersect some surfaces. Ultimately the database consisted of a watertight model.

Meshing Santa’s Hat with Automatic Surface Meshing

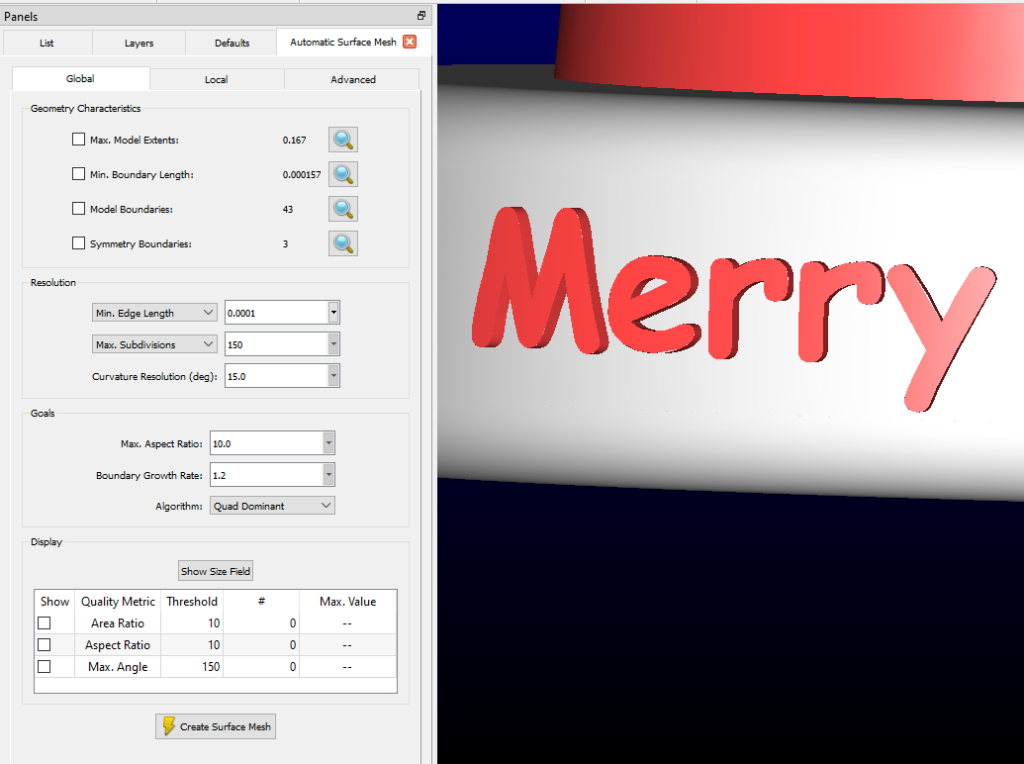

Using Automatic surface meshing couldn’t have been much easier. By selecting the model and Create->Automatic Surface Mesh we were presented with the panel in Figure 2. This allows faster feedback for the surface mesh required in terms of mesh metrics and sizes.

Without Automatic Surface Meshing, the database would have been converted to domains by “Domains on database”, and the connectors and domains would have been manually adjusted iteratively (using Examine to check the mesh quality) to come up with a surface mesh of good enough quality. Compared to Automatic Surface Meshing, this was a reasonably time-consuming process more prone to user error.

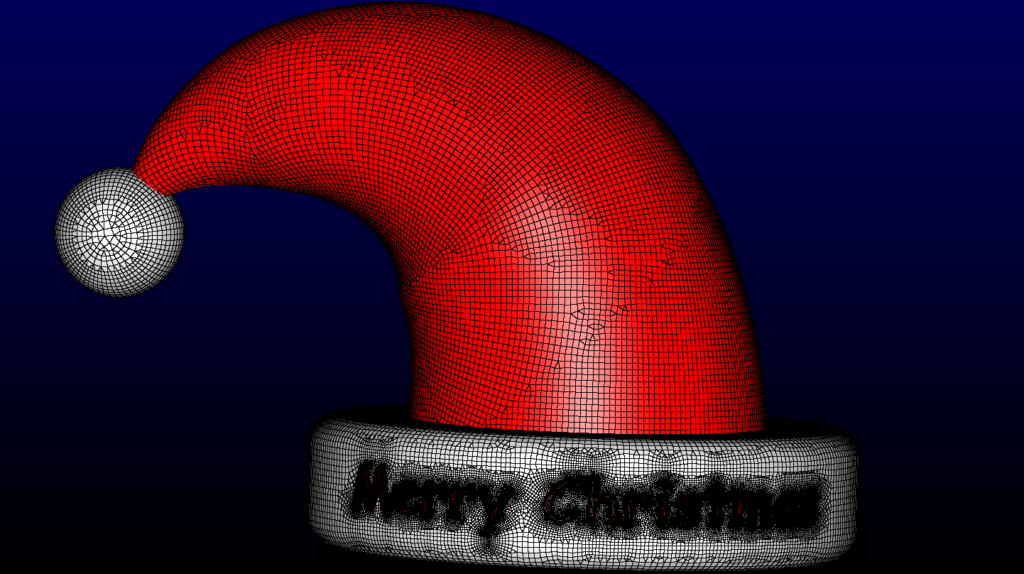

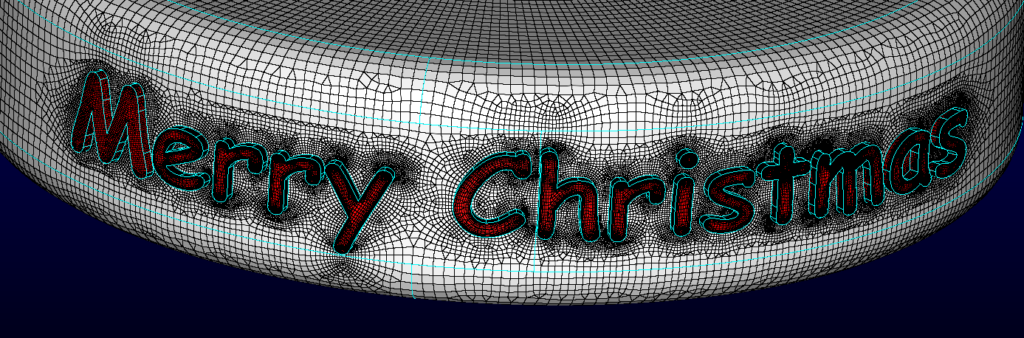

The final mesh is shown in Figure 3, and we can see quad dominant mesh with a good quality as we specified.

A zoomed view of the final mesh is shown in Figure 4, and we can see quad dominant mesh is very uniform away from features, and suitably refined near letters.

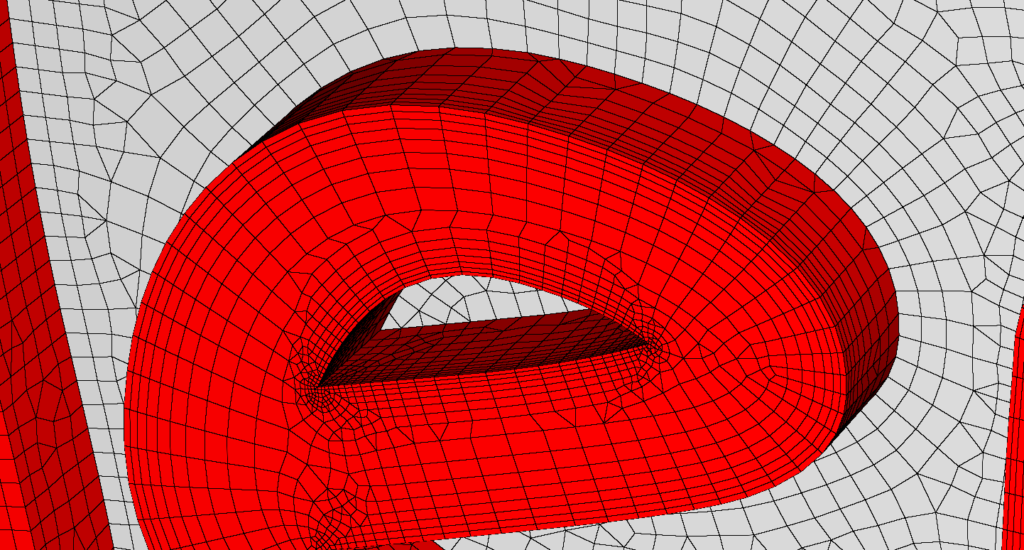

A zoomed view of a letter is shown in Figure 5. Showing the anisotropic 2D T-Rex surface mesh provides excellent quality quad cells that respect the sharp edges. 2D T-Rex mesh was set up automatically by Pointwise’s Automatic Surface Meshing, and the goal metrics were Max aspect ratio of 10, boundary growth of 1.2, curvature resolution of 15 degrees and max subdivision of 150.

Thanks for reading, the next edition will be in 2021. Until then, happy meshing, and happy Christmas!

To learn more about Pointwise, go here, or for a free trial of Pointwise, go here.

20.

Meshing Santa’s Hat